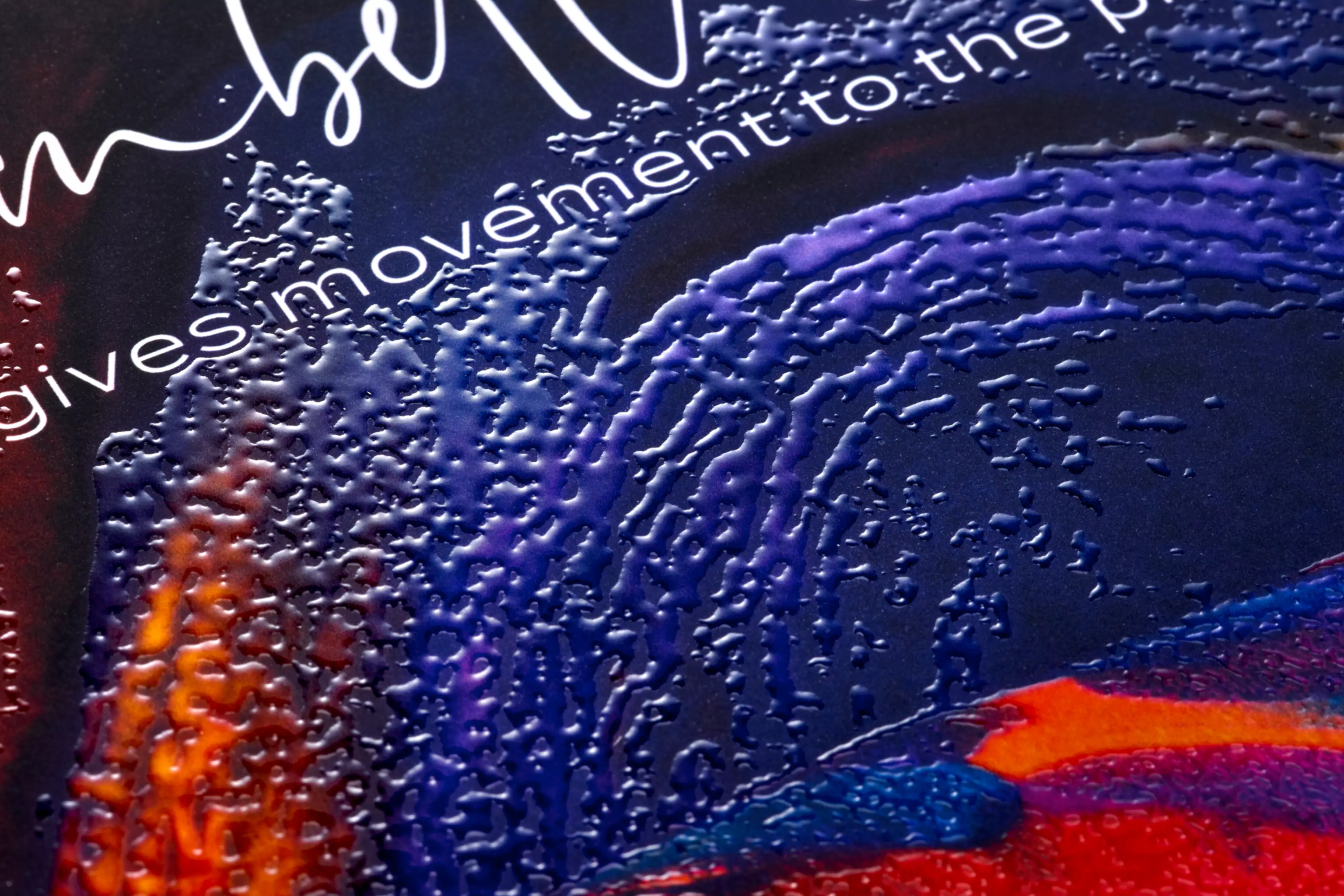

As brand owners seek more sustainable packaging, faster customization, and shorter production cycles, the inkjet market is expanding rapidly. According to Future Market Report, the Industrial Inkjet Printheads market is projected to reach USD 3,450 million by 2032, growing at a CAGR of 8.9% from 2025 to 2032.

A key driver behind this growth is the technological innovation of printhead manufacturers, who are pushing the boundaries of image quality, speed, and material compatibility.

Advances such as higher dpi resolutions, smaller drop volumes, and improved ink recirculation and temperature control, are enabling finer detail, greater productivity, and the use of a wider variety of inks - including water-based and UV-curable formulations -across diverse substrates.