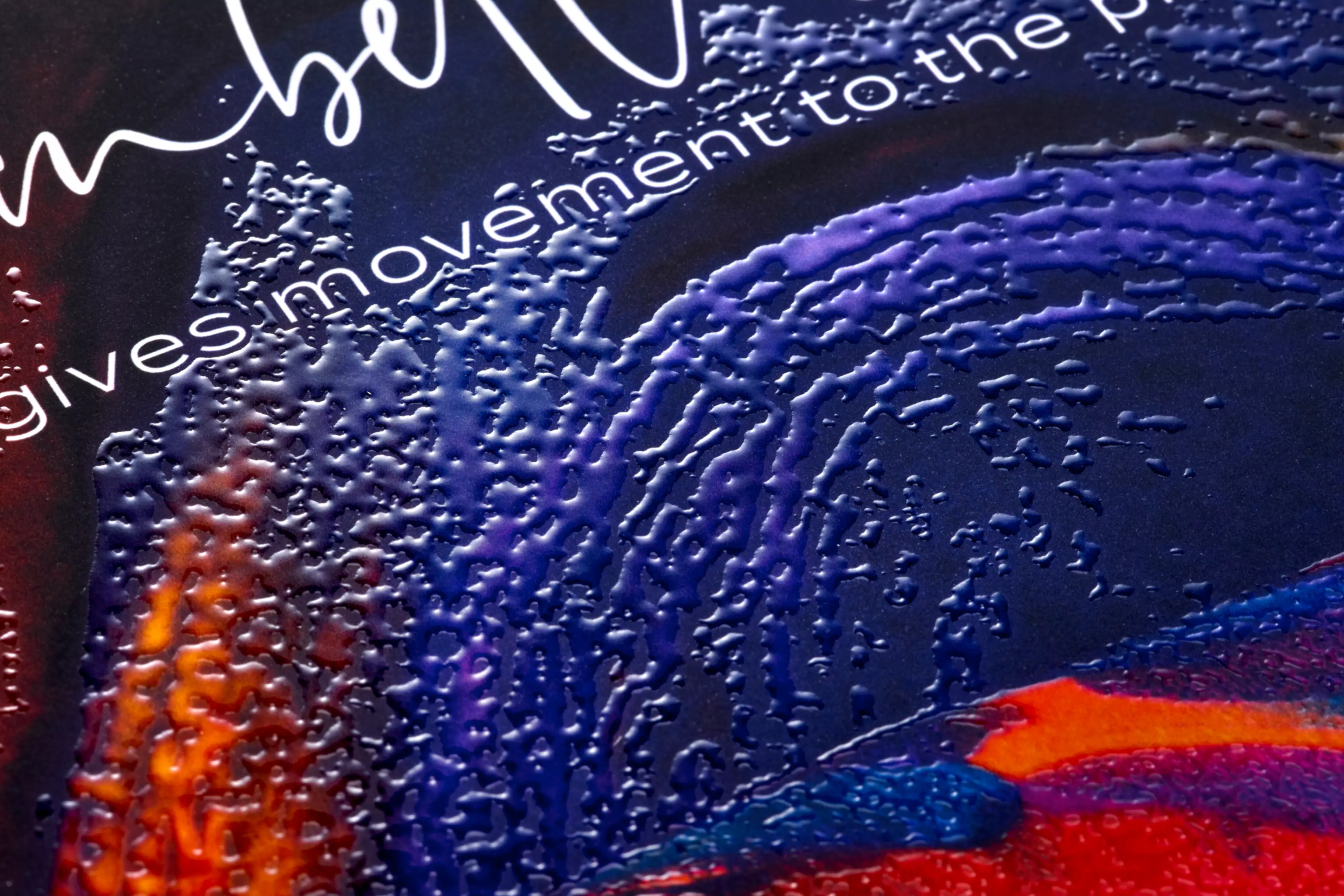

New ways to ensure you are getting the most from your digital printing technology were a major focus throughout drupa. Significant enhancements in the print production results delivered by the latest inkjet innovations were showcased. Developed to aid digital transformation across commercial and industrial printing markets, and address a wider set of application needs, enhanced high productivity inkjet printing was presented.

Visitors were able to explore advanced digital production lines that offer seamless integration for cutting edge high-speed cut-sheet toner and production inkjet presses, while inline sensors allow continuous monitoring and control of the printing process to ensure efficient and consistent high-end production. There were also broader conversations around ever-increasing opportunities for flexible packaging and corrugated printing.

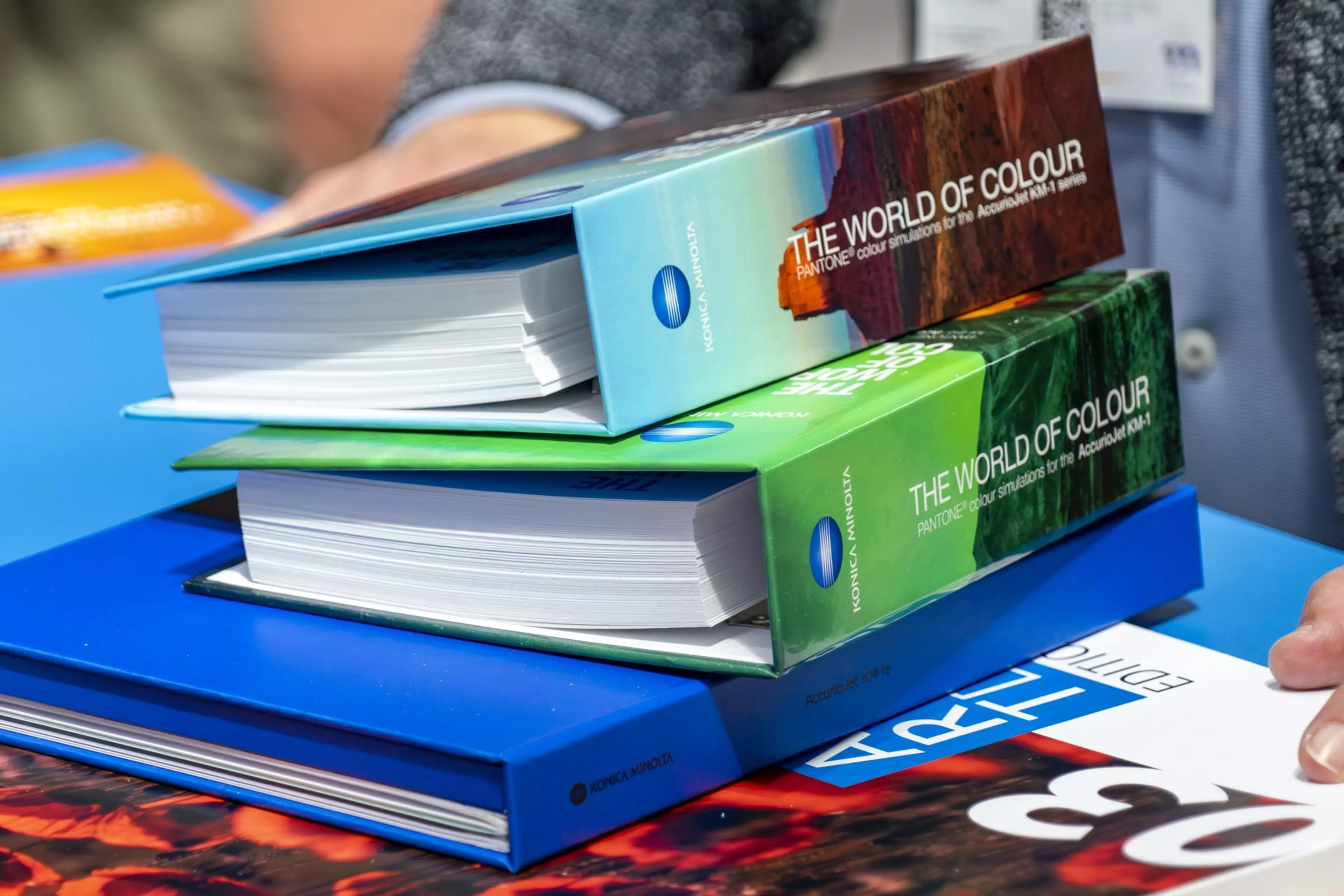

Leveraging technology innovation, alongside software solutions for automation and colour management, will maximize productivity and output quality as well as drive growth and deliver cost effectiveness. In particular software solutions can deliver comprehensive integrated colour management that streamlines workflows, seamless functionality with internal and external measurement devices and enhanced production workflow analysis. They can ensure greater shopfloor reportability, reducing downtime as well as costs related to production, while maximizing the overall productivity through comprehensive device evaluation. They can also provide greater intelligence to better support high-volume, high-quality, on-demand print-related business decisions.

Also supporting this is investment in staff training to fully utilize in-house digital production capabilities, integrated software solutions for workflow automation, and regularly reviewing print industry innovation to stay current with the latest advancements.

2 Producing more jobs efficiently and cost-effectively

Among the benefits of digital print production that can be maximized is producing jobs more cost effectively. This can be achieved by implementing end-to-end digital technologies that can enable a smoother production process, from brand planning, to e-commerce, to printing, to logistics.

Automation of processes, such as setup configurations and software-driven operations, can increase efficiency, drive growth and reduce costs. The significant opportunities for operations to implement fresh innovation via automation were highlighted by drupa’s own Print Horizons report. It stated globally that 29% of companies had not started to automate their processes while more than half (54%) had prepress automation, 35% had press and post press automation and 13% end to end JDF workflow. In Europe nearly a quarter (24%) of printers had none of the above.

To assess where positive, value-added, changes can be made, operations should first evaluate real-time workflows for inefficiencies and then explore opportunities for integrating software solutions, including cloud-based innovation, to optimize job production, including considering which partner can help them develop the right approach for their production demands. This ensures they have the information they need to invest in the right automation technologies.

The creativity and versatility enabled by digital print can power creative variable data printing that allows runs of one to be produced efficiently and cost effectively. With the right software tools marketing collateral and any other material can be easily customized in a minimum of time. The entire process can even be automated. The result is enhanced competitiveness and boosted business.

If drupa 2024 showed anything it was the impact of integrating of AI into printing processes. drupa’s Print Horizons reported the technology’s wide industry use in monitoring and analysing machine performance data to assist predictive maintenance schedules. It pointed to greater adoption to make better use of materials, reduce waste and help with quality control. It warned the industry should prepare for an influx of files with text and images created by AI. All were with operational efficiency improvements and manufacturing processes in the supply chain in mind.

One area where the use of AI is proving particularly effective is in Programmatic Printing with AI-generated content enhancing personalization, improve targeting, and optimize printing processes. Visitors were able to explore user-friendly AI-driven software solutions tailored to the printing industry, including Programmatic Printing. It is adding AI-generated content to applications for totally targeted communications. They were also able to consider ways how AI evaluates and refines algorithms to improve efficiency and effectiveness.

AI also plays a role in addressing the large-scale problem of fewer skilled employees. Tedious tasks can be taken over by AI and working time can be increasingly used for creative tasks. Also supporting employees is Industry 5.0 with a focus on human centricity. It considers how new technologies can better support employees and make work easier with solutions such as increased automation and highly effective remote servicing operation. drupa’s Print Horizons agreed the main reason for operations across commercial, publishing and packaging sectors considering investment was automation to support less skilled staff.

There are a number of factors in play. One key challenge is the rapid pace of technological advancement. Skill requirements have evolved with the introduction of digital printing, automation, and data-driven processes and the transition to these technologies often requires a specialist. Another contributory factor is the aging workforce. As experienced professionals retire, gaps are opening up in skills and knowledge that should be filled by experts such as prepress technicians, machine operators, and colour management specialists. Also having an impact is the perception of the industry as being outdated. Few people are aware of the range of career opportunities possible from graphic design and sales and marketing to print production. This is where promoting the exciting and innovative aspects of the industry can dispel this outdated misconception.

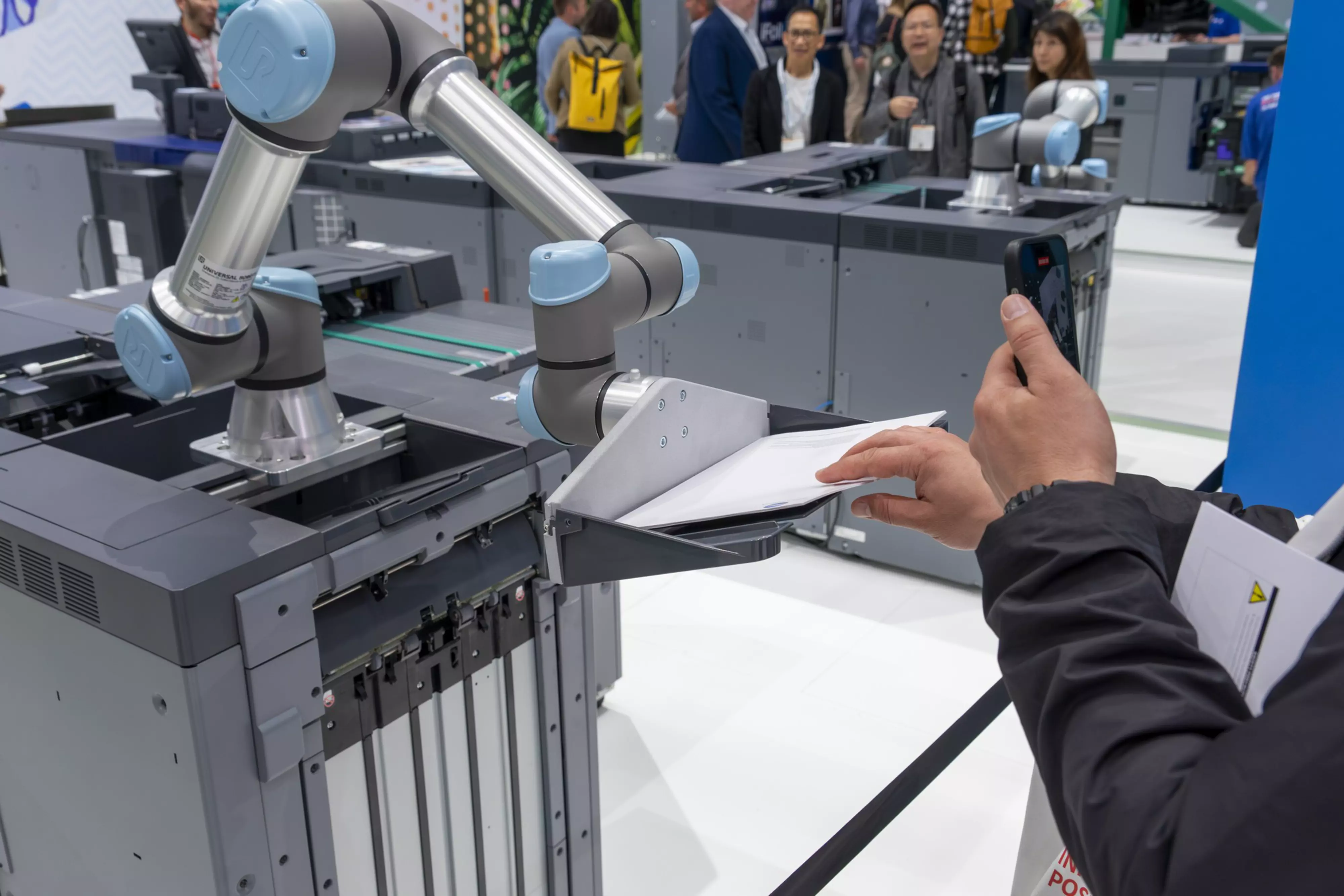

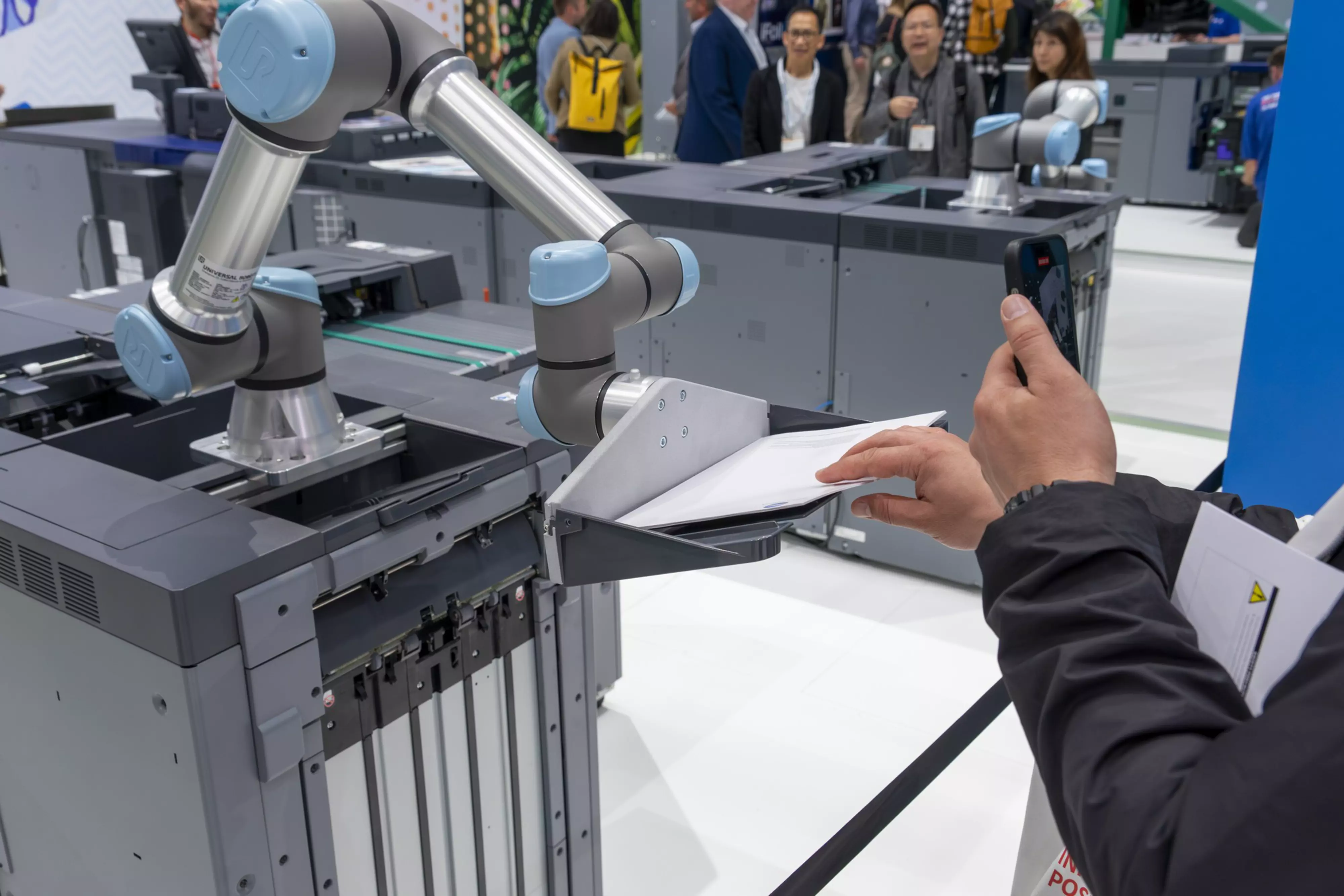

In every day operation the skills gap can be compensated for by leveraging robots to increase productivity and keep efficiency levels high to enable employees to focus on higher-value activities. Robots can also help shorten lead times, reduce the risk of bottlenecks, and optimize safety.

Remote servicing operations, and specialized software tools can increase operational efficiency as well. So too, can investing in training programmes for existing staff to enhance their skills.

The theme of sustainability and print's environmental impact was a central thread throughout the show. drupa’s Print Horizons reported that neither operations, or their suppliers, can afford to ignore it. This was also true because actions taken to increase sustainability are often good for the bottom line and frequently required by customers. Many operations are well aware of this and have implemented some sustainable strategies. In fact, 55% of all printers surveyed have a sustainability policy with specific goals and targets. This figure is true both globally and across all markets.

Visitors were keen to see a commitment to sustainability, demonstrated through initiatives such as using recycled materials and sustainable production practices – an approach that minimizes waste while enhancing brand reputation.

For those who want to understand how to affect change, best next steps include conducting a sustainability audit to identify areas for improvement, investing in eco-friendly technologies, and communicating sustainability efforts to customers and stakeholders.

These were among the forward-thinking conversations that took place at drupa exploring how operations can address these key challenges in digital production and industry shaping trends. How they can maximize efficiency, leverage AI capabilities, mitigate skill shortages, and ensure their operation improves its sustainability.

Contact us to learn more about how we can help you “See the Potential in the Future of Print” with the aid of the latest highly automated technology innovations, efficient systems and easy-to-use solutions.