Labels are a growing part of the printing market, they continue to drive demand for creative, high-quality output. As marketing becomes more focused and competitive, so does the need for attention-grabbing labels. Critically, constantly changing regulations and a shift toward small and medium size print runs forces label converters to keep pace at the expense of profits.

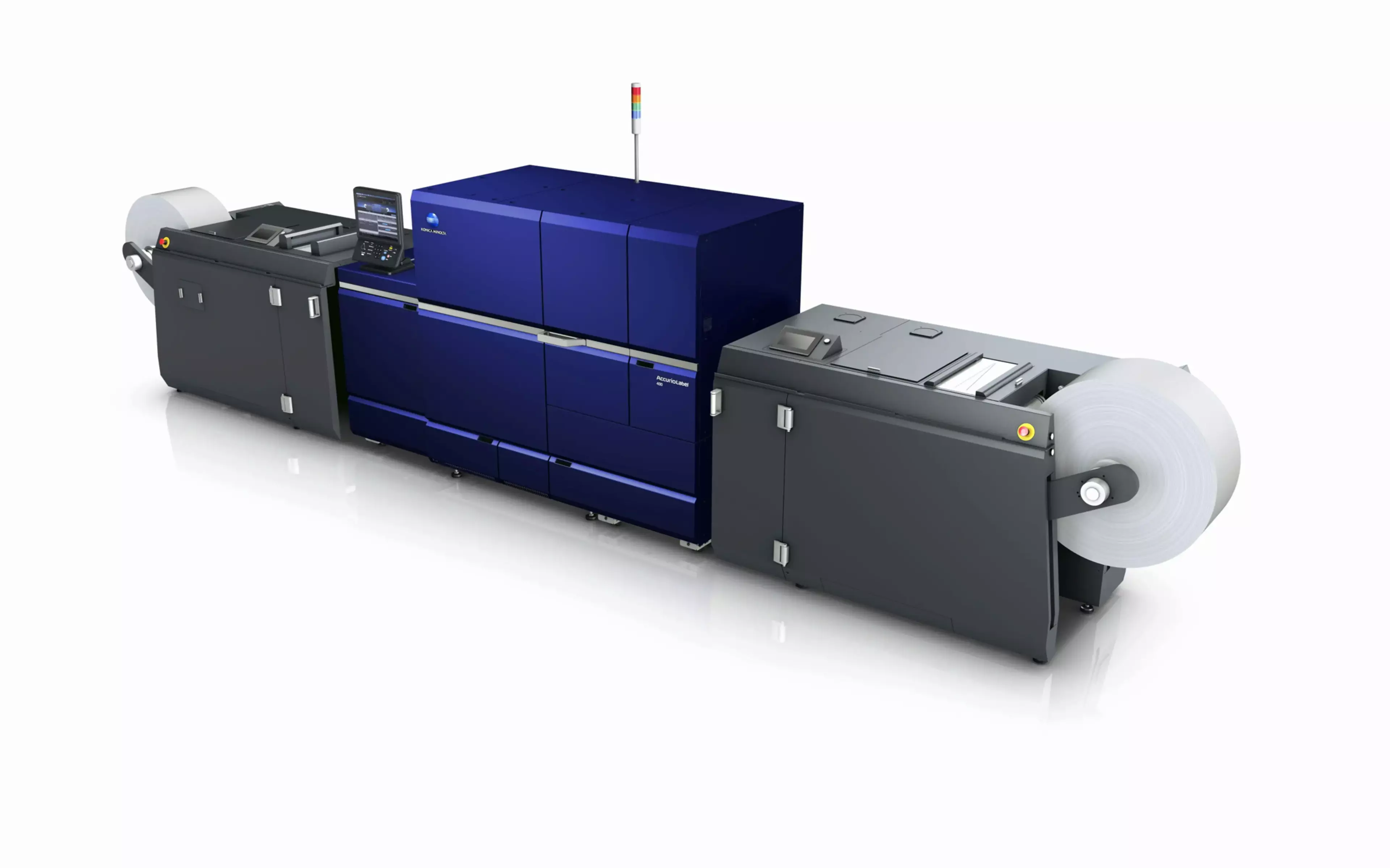

To stay afloat in a changing industry, you need to get more profit from an increased turnover of small-lot, hybrid print jobs. Which demands a digital solution. Pairing an MGI JetVarnish 3D Web 400 embellisher with AccurioLabel 400 will deliver fast, fuss free, small-lot production. Then printing high-impact, value-added colour labels is like printing profits.