Low energy consumption, certified de-inking or high quality printing on recycled paper: With digital inkjet printing you are on the right track towards more environmental responsible printing. Add to this the overall print quality that sheetfed offset can just about match, and you are excellently equipped for your next customer meeting - also when it comes to environmental topics.

Modern inkjet printing is one of the fastest growing printing processes. By 2032 according to Smithers Pira, more than 3/4 of the total digital print volume will be produced on inkjet systems. But what makes this print technology so special for print buyers and their printers? Print quality, colour stability and flexibility are some of the aspects that make digital inkjet so attractive: for some years now these systems have been achieving the same or even higher quality than offset processes. And inkjet also scores points in terms of environmental issues, for example through low energy consumption.

What inkjet does in terms of sustainability

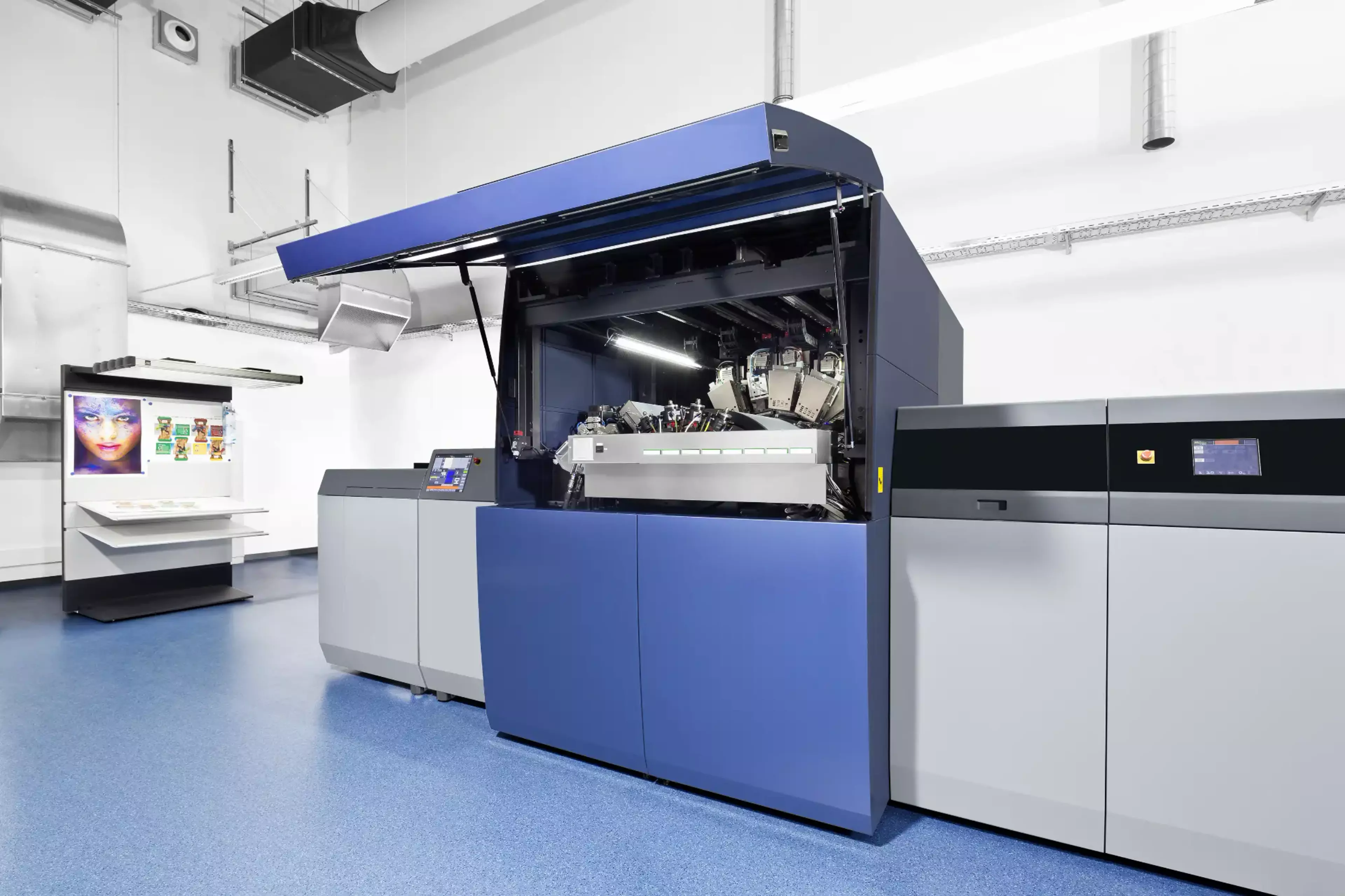

Let's take a look at our B2+ sheetfed AccurioJetKM-1e series to see how modern inkjet systems can help you to produce economically without neglecting important environmental issues (often connected with printing) at the same time.

More and more printers are shifting their production from offset to digital - for good (economic) reasons. With the possibility of hybrid printing by integrating theKM-1e into existing processes, automatic perfecting and the option to use larger sheet sizes and print on a wide range of substrates, the KM-1e series closes this gap. And all this also serves sustainability. So should your customer ask you why they should buy digital inkjet printing, here are 5+1 reasons for you:

Low energy consumption. Due to its principle, digital printing does not require any printing plates that have to be exposed in an energy-intensive way. Thanks to the precise inkjet output control, there is no need for tedious colour matching between devices, which significantly shortens print preparation. Also, thanks to LED curing, there is no need for drying time, which enables automatic duplex printing of the highest quality. Taken together, we estimate energy savings of up to 50% compared to analogue offset processes. In addition, technical enhancements have enabled us to significantly reduce the energy consumption of the KM-1e compared to its predecessor - by up to 40% for shorter runs.

Use of recycled paper: Better than any other printing technology, digital inkjet printing is able to produce on recycled paper. Unlike water-based ink systems, the KM-1e delivers first-class images with crisp text and high line quality even on difficult substrates.

Certified de-inking: De-inking is the key process for paper recycling and therefore saves natural resources. Important process steps in de-inking are the removal of the ink pigments from the paper, the fragmentation of the ink into a defined size range and the removal from the pulp. Only after completing de-inking can the paper be fed into the recycling process. Our KM-1e series is the only B2 digital printing solution on the market with INGEDE deinking certification for coated papers, which even includes recycled materials. This means printers of all sizes can take a big step towards greater sustainability. Our system has passed all the tests of the International Association of the Paper Recycling Industry with flying colours. Also, important to know: The KM-1e series ink contains no mineral oil.

Less input materials/less waste: With classic standard inkjet processes, the printed image often has to be protected with varnish to protect the printed image. Our advanced inkjet technology makes this unnecessary. This saves the use of auxiliary materials and serves sustainability. Another aspect: an end-to-end digital printing process is able to significantly reduce the use of substrates. Thanks to outstanding colour stability and consistency on every sheet in the print run, waste is kept to a minimum.

No VOC formation: The KM-1e printing process does not produce any volatile organic compounds (VOCs) that can have health effects. In addition, this printing process requires little water and no alcohol. It also allows for more advanced and profitable applications. For example, the KM-1e has the international certification EN 71 "Suitability as a Toy" from the German TÜV Rheinland. The testing organisation thus confirms that prints produced on the system comply with all national and international standards for the safety of toys.

These are already 5 good reasons why modern inkjet is a smart and environmentally responsible solution.

And yet print buyers or agencies are often sceptical when it comes to the environmental assessment of ink-based technologies. The reason lies in prejudices that date back to offset times and relate to the curing process that is common there. "UV" simply does not sound like environmental compatibility. So here is an additional reason in favour of digital inkjet:

Modern curing with light has evolved considerably. Instead of questionable mercury vapour lamps, LED lamps are now used for UV curing. These LED lamps no longer emit active light below 235nm and require only a fraction of the energy. Thanks to the closed production room of the KM-1e series, there is also no UV exposure of the operating personnel. Modern LED technology is therefore environmentally friendly and safe.

Environmentally advanced printing

LED-based inkjet is characterized by more sustainable production processes and environmentally advanced components. In the future, this printing process will continue to gain acceptance as a technology with many features supporting an environmentally conscious printing era. You can use LED-UV printing safely without endangering your staff or the environment. Thanks to solvent-free UV ink, you can improve your printing processes without worrying about releasing harmful substances into the surrounding air.

Learn more about the future of printing

Read here how our UV inkjet technologies can help you increase profitability, build a new business, increase flexibility and print more productively.