Increase Efficiency | Reduce Production Delays | Minimise risk

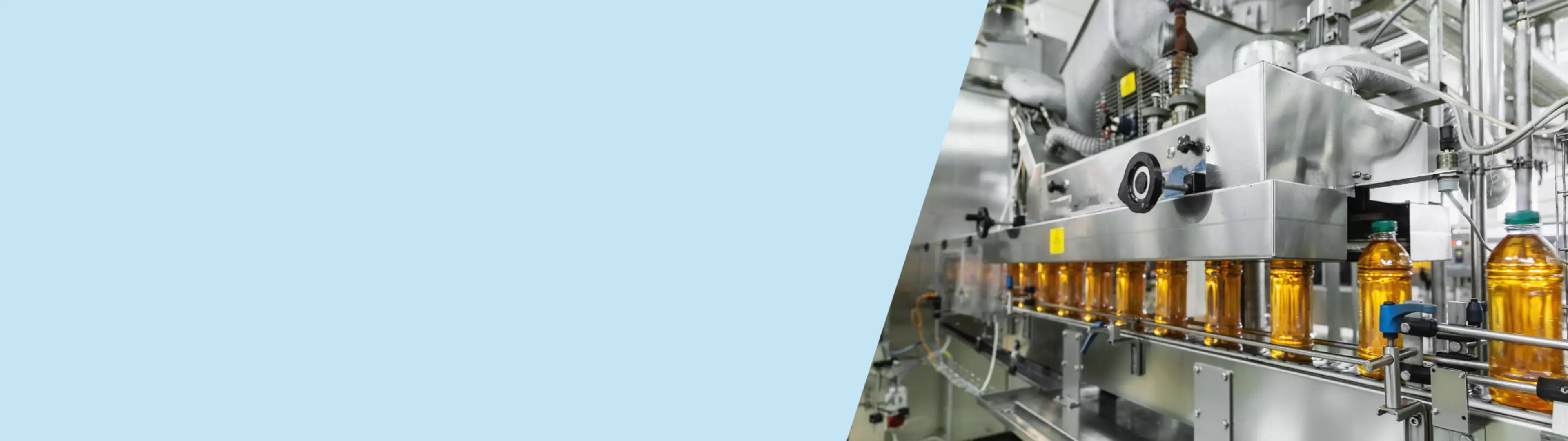

Quality control in manufacturing, logistics, warehouse and similar environments is a critical but expensive and time-consuming process. In a complex or high-speed environment, human inspectors may struggle to keep pace, or may become distracted or fatigued — potentially leading to defects, anomalies and other issues being missed.

As a result, defective or improperly packaged products can get shipped, industrial processes can incur downtime, and worker safety can even be compromised.

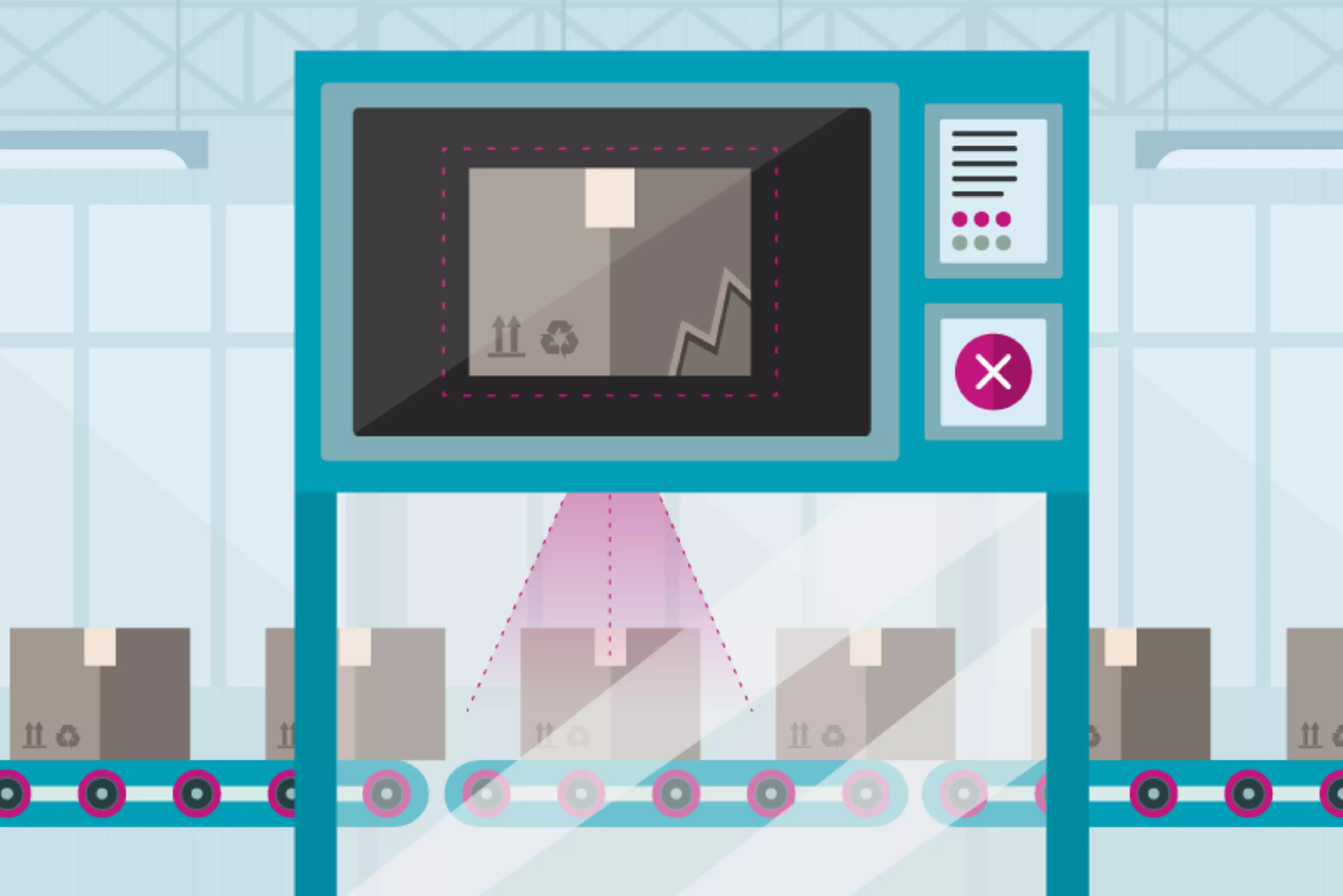

Maintain consistently high standards with video-based inspections. With an intelligent video-based solution you can make visual quality inspection a much more consistent, reliable process. At Konica Minolta we've developed Visual Quality Inspection (VQI) solutions based on smart IoT-based Mobotix video cameras combined with FORXAI, our imaging IoT platform. FORXAI enables immediate AI-based processing of camera images and video — on site or in the cloud — enabling visual inspection of any production, logistics, warehouse or other industrial process.

Our Visual Quality Inspection solutions

Visit our Showrooms Website!

Step Inside the Future

As you step into our showroom, you're not just witnessing technology; you're experiencing a transformation. It's a journey into a world where AI and human ingenuity collaborate to redefine what's possible. Our showroom is a testament to the fusion of technology, innovation, and a relentless pursuit of perfection.

Join us on this journey of discovery, where the possibilities are limitless, and the future is now. Welcome to a showroom that doesn't just showcase solutions; it defines them.

Your benefits at a glance

Consistently high levels of visual quality inspection at all times

Alerting to anomalies or other issues enabling rapid automated or human intervention

Reduction in production downtime, manufacturing delays and excess costs caused by defective products

Increase in product or packaging quality, leading to benefits such as increased customer satisfaction and less waste

Easy-to-use dashboards support real-time action as well as historical analysis

Highest Quality Standards through zero-defect production

Do you work with quality control inside an assembly line using human inspection? Are you spending lots of valuable time checking for cracks, deformation, dirtiness and missing or incorrect components in your products? Learn here how automated visual quality inspection can support you and help to save time and money.

Visual Quality Inspection: Highest quality standards through zero-defect production

Visual Quality Inspection is Konica Minolta’s deep learning-based monitoring system which ensures highest quality standards through zero-defect production, thereby improving production processes, both in terms of safety and efficiency. It is based on FORXAI, Konica Minolta’s image IoT platform that accelerates the digital transformation of society together with customers and partners.